EVA Tool Bag Density and Protective Performance Correlation Chart

For tool storage and transportation, EVA tool bags are a top choice for professionals and enthusiasts due to their lightweight, wear-resistant, and impact-resistant properties. However, many people make the mistake of focusing solely on appearance and capacity while overlooking the core indicator of protective performance: density. In fact, the density of EVA material is directly related to the tool bag’s drop resistance, shock absorption, and durability. Choosing the right density ensures truly reliable protection for your precision tools. This article will use the “EVA Tool Bag Density and Protective Performance Correlation Chart” to deeply analyze the inherent relationship between the two and teach you how to accurately select the right model based on the type of tool.

First, let’s understand: What is EVA density? Why does it affect protective performance?

Before discussing this correlation, we must first clarify two key concepts: the definition of EVA material density and the core dimension of protective performance.

1. Definition and Common Range of EVA Density

EVA (ethylene-vinyl acetate copolymer) is an elastic material created by adjusting the vinyl acetate (VA) content and foaming. Its “density” is typically measured in grams per cubic centimeter (g/cm³) or kilograms per cubic meter (kg/m³), referring to the mass of EVA material per unit volume.

In the tool kit industry, common EVA densities range from 0.3g/cm³ to 0.8g/cm³ (or 300kg/m³ to 800kg/m³). This density difference primarily stems from the foaming process: low-density EVA has large, dense cells and a soft texture; high-density EVA has small, dense cells and a hard, stiff texture.

2. Three Core Evaluation Dimensions of Protective Performance

For tool bags, “protective performance” isn’t a vague concept; it’s a quantifiable capability measured through the following three metrics:

Impact resistance: The material’s ability to absorb and disperse impact force during external impacts (such as drops or crushing), preventing damage to the tools inside;

Shock absorption: The ability to cushion the impact of vibrations on precision tools (such as instruments and knives) during transportation;

Structural stability: Whether the material maintains its shape and resists deformation after long-term use, ensuring that tools remain securely in place.

The performance of these three dimensions is almost entirely directly determined by the density of the EVA.

II. Core Essentials: EVA Tool Bag Density and Protective Performance Correlation Chart and Analysis

To provide a clear understanding of the relationship between density and protection, we’ve compiled a performance comparison chart for EVA tool bags in different density ranges, and provide detailed explanations of the applicable scenarios for each range.

Density Range (g/cm³)

Appearance and Texture

Impact Resistance

Shock Absorption

Structural Stability

Weight

Applicable Tool Types

Typical Usage Scenarios

0.3 – 0.4

Soft and Flexible

Weak

Excellent

Poor

Light

Small and Lightweight Tools (e.g., screwdrivers, USB flash drives)

Daily Carry, Short-Distance Travel

0.4 – 0.6

Moderate and Supportive

Medium

Good

Medium

Medium

General Tools (e.g., wrenches, small instruments)

Workshop Use, Short-Distance Transport

0.6 – 0.8

Hard and Stiff

Strong

Medium

Excellent

Heavier

Precision/Heavy Tools (e.g., measuring instruments, knives)

Long-Distance Transport, Outdoor Work, Warehousing

1. Low Density Range (0.3-0.4g/cm³): Lightweight and Suitable for “Light Protection”

Performance Characteristics: This Type of EVA The tool bag’s texture is as soft as a sponge, offering excellent elasticity and light weight, making it a breeze to carry. However, due to its large foam cells and loose structure, it has low impact resistance and can easily deform with long-term use.

Protection Principle: The material’s elasticity primarily cushions minor vibrations, rather than protecting against strong impacts.

Applications: Suitable for storing small, everyday tools such as household screwdriver sets, tweezers for electronics repair, and USB flash drives. For example, many digital enthusiasts use this density EVA bag to store spare camera batteries—it’s lightweight, compact, and prevents scratches from friction between batteries.

Note: It’s not recommended for use with precision instruments or heavy tools, as it can easily damage the contents if dropped or squeezed.

2. Medium Density Range (0.4-0.6g/cm³): A versatile choice that balances protection and portability.

Performance: Medium-density EVA is the most popular choice on the market. It offers a certain degree of softness (good shock absorption) while also providing sufficient support (resistance to deformation). Its impact resistance is sufficient for most daily use, while also being lightweight for portability.

Protection Principle: Through the dual functions of “elastic cushioning + structural support,” it absorbs vibrations during transportation while maintaining its shape during minor impacts, preventing tool shifting.

Applications: Covers most common tools, such as wrench sets for car repairs, multimeters for electricians, and small laser rangefinders. For example, many tool waist bags commonly used by workshop workers are lined with EVA of around 0.5g/cm³. This allows them to secure tools without adding too much weight to the waist. On short business trips, these EVA tool bags can be used to store laptop chargers and adapters, preventing them from being crushed by other items in a backpack.

Advantages: Highest value for money, balancing both protection needs and user experience, making them suitable for most users.

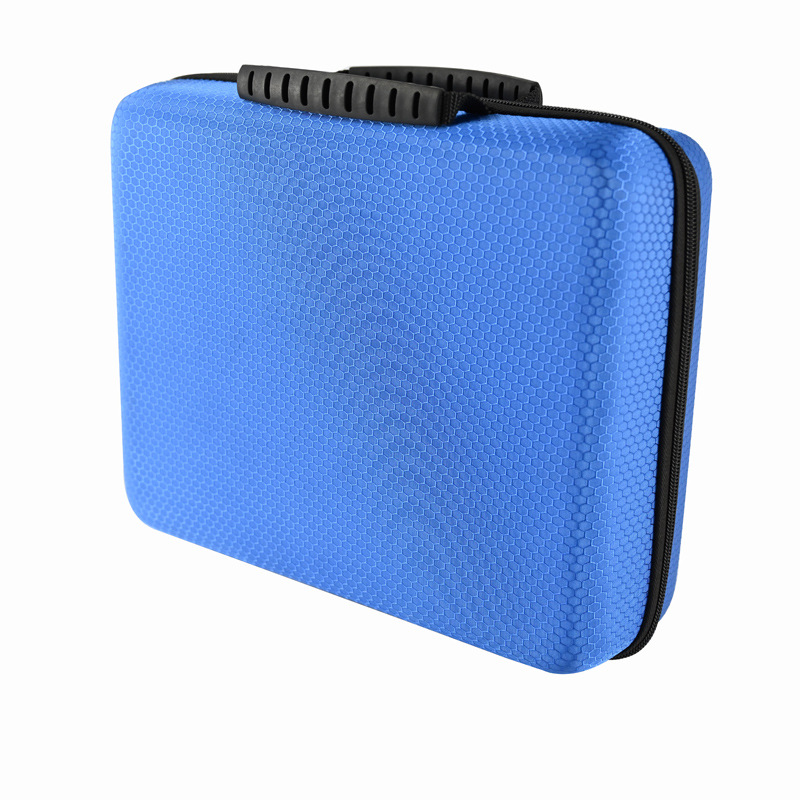

3. High-density range (0.6-0.8g/cm³): Ultimate protection for high-value tools

Performance: High-density EVA tool bags feel hard and stiff, like hardshell luggage, and offer exceptional impact resistance, effectively protecting items even from drops of 1-2 meters. They also offer excellent structural stability, resist deformation over time, and securely secure tools. However, their weight can be a disadvantage, making them relatively inconvenient to carry. Protective Logic: Relying on a dense foam structure to directly resist external impact, while the material’s inherent rigidity secures the tool and reduces friction during vibration.

Applications: Designed specifically for protecting high-value, high-precision, or fragile tools, such as industrial micrometers, surveying total stations, small medical diagnostic instruments, and engineer shovels used in outdoor operations. For example, geological surveyors use 0.7g/cm³ EVA hard-shell tool bags to carry core sampling tools while on the move. This minimizes damage to the instruments from bumps on rugged mountain trails or accidental drops. Knife enthusiasts also choose high-density EVA-lined cases for their high-end folding knives to protect the blade from dents and oxidation.

Note: Due to its heavy weight, it is more suitable for stationary use (such as storage or vehicle storage) or professional use. It is not recommended for frequent daily transportation.

Third, Practical Guide: How to choose the right EVA density for your tool? 3 steps! After looking at the correlation table, many people may still ask, “Which density should I choose for my tool?” Don’t worry! We’ve summarized three simple steps to help you find the right density.

Step 1: Evaluate the “Core Requirements” of the Tool

First, ask yourself two questions:

Is the tool sensitive to drops? (e.g., precision instruments, glassware → require high impact resistance)

Is the tool sensitive to vibrations? (e.g., electronic components, sensors → require high vibration damping)

Does the tool need to be secured? (e.g., irregularly shaped tools, sharp knives → require high structural stability)

For example:

Conventional tools like screwdrivers and wrenches: Not sensitive to minor vibrations but sensitive to severe impacts → Medium density is recommended;

Laser rangefinders and multimeters: Sensitive to both vibrations and drops → Medium-to-high density (0.5-0.6 g/cm³) is recommended;

Micrometers and scalpels: Extremely sensitive to drops and require precise securing → High density (0.7-0.8 g/cm³) is essential.

Step 2: Consider the “Usage Scenario”

For the same tool, the density selection will vary depending on the usage scenario:

Daily carry (e.g., carrying tools to and from work): Prioritize lightness → Choose low or medium density;

Long-distance transportation (e.g., shipping tools to customers): Prioritize protection → Choose high or high density;

Outdoor work (e.g., construction sites, field exploration): Require both protection and durability → Choose high density;

Desktop storage (e.g., fixed-use storage in the studio): Require both protection and aesthetics → Choose medium density.

Step 3: Verify by referring to “Product Specifications”

When purchasing, always check the “EVA Density” parameter on the product details page (if it’s not listed, contact customer service). Also, pay attention to the following two details:

Inner Liner Thickness: For the same density, the thicker the inner lining, the better the protection (for example, 0.6g/cm³ EVA at 5mm thickness has better impact resistance than 3mm).

Foaming Process: High-quality “closed-cell” EVA is more water-resistant and deform-resistant than “open-cell” EVA, and thus offers superior protection even at the same density.

Fourth, Common Misconceptions Debunked: Three “Assumptions” About EVA Density and Protection

Many people are misled by misconceptions when purchasing. Here, we debunk three common misconceptions:

1. Misconception 1: Does a higher density necessarily mean better protection?

Truth: Not necessarily! Protection is a combination of “density + thickness + process.” For example, EVA with a density of 0.8g/cm³ but only 2mm thick may not offer as much protection as EVA with a thickness of 0.6g/cm³ but 8mm thick. Furthermore, if your tools are sensitive to shock and drop (such as electronic components), a high-density hard shell may not provide sufficient shock absorption, potentially damaging them.

2. Myth 2: Low-density EVA is “not durable” and can only be used a few times?

Truth: The durability of low-density EVA depends on its usage. If used to store lightweight tools and protected from frequent impact and shock, it can last for 1-2 years without a problem. However, if used for heavy tools or subjected to rough outdoor use, it can easily deform and damage.

3. Myth 3: The heavier the tool bag, the higher the density?

Truth: Weight is affected by “density + volume.” A large, medium-density EVA tool bag may be heavier than a smaller, high-density one. Density shouldn’t be judged solely by weight; it must be considered in combination with volume and feel.

Fifth, Conclusion: Choose the right density to make your EVA tool bag a “tool guardian.”

The density of an EVA tool bag isn’t “higher, the better”; it’s “more appropriate, the better.” Keep these key principles in mind:

For lightweight portability, choose low density (0.3-0.4g/cm³): Suitable for everyday small tools;

For balanced practicality, choose high density (0.4-0.6g/cm³): Covers most common scenarios and offers the best value for money;

For ultimate protection, choose high density (0.6-0.8g/cm³): Protects delicate, heavy, or high-value tools.

Post time: Sep-08-2025