How to Choose the Right EVA Tool Kit for Your Needs

1. Accurately Identify Requirements: Identify Core Needs from the Application Scenario

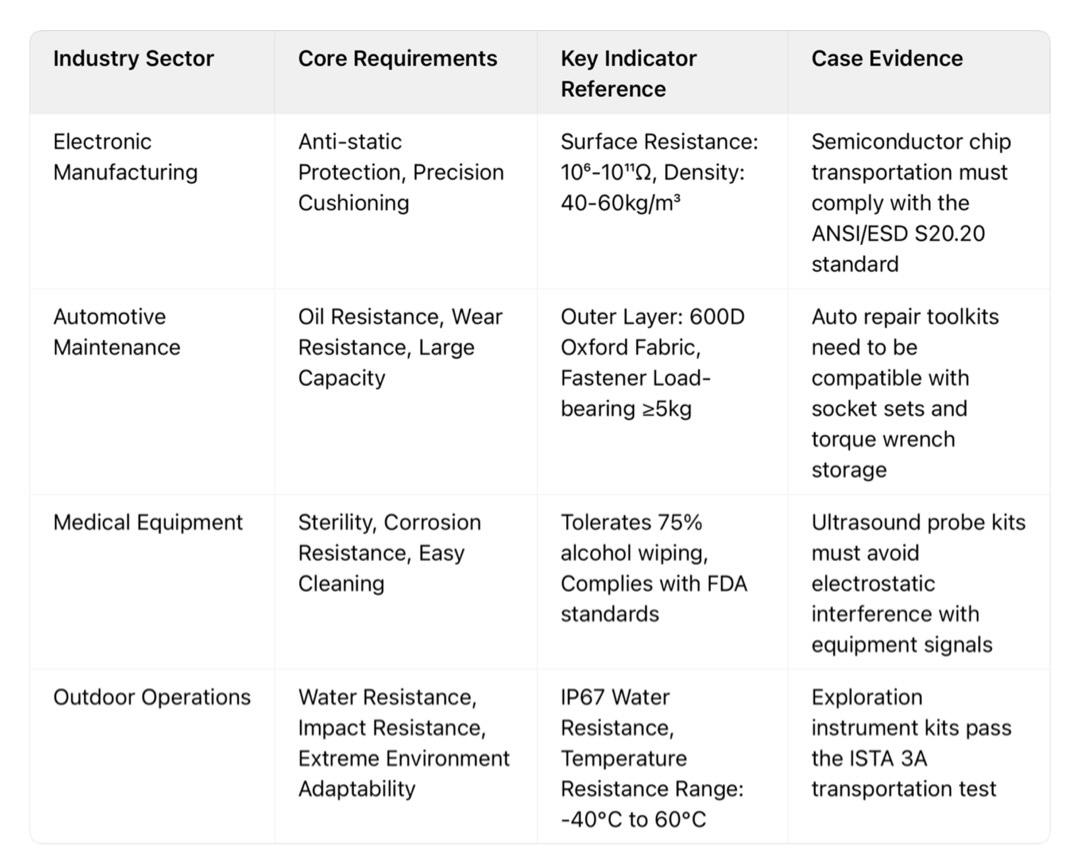

The first step in professional procurement is to clearly define the tool kit’s “mission.” Different industries have vastly different requirements for protection, storage, and environmental adaptability. Choosing the wrong tool can lead to damage, noncompliance, and even safety risks.

1. Decision by Industry Scenario

Size Matching: Calculate based on the maximum tool size + a 2cm buffer (e.g., a Fluke multimeter case measures 315×174×104mm, precisely fitting the device).

Load Estimation: For standard tool bags, we recommend selecting a load capacity of 1.5 times the actual load weight (hardware tool bags must be ≥15kg).

Frequency of Use: For frequent use, choose a hot-pressed, one-piece molding process (3x more durable than sewing).

II. Material Selection: Unlocking EVA’s Core Performance

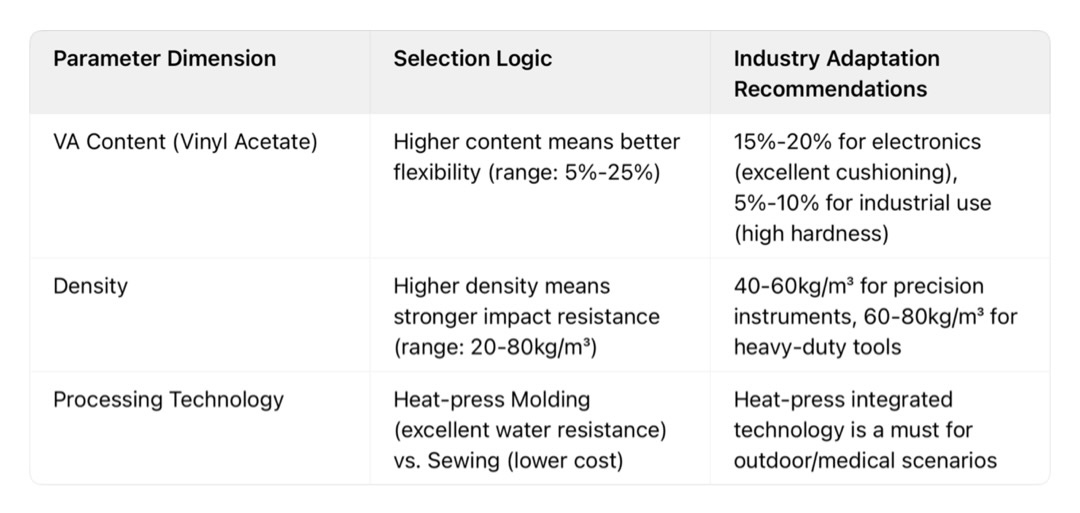

The performance differences of EVA materials stem from the VA content, density, and processing technology, which directly determine the protective capabilities and lifespan of the tool bag.

1. Core Parameter Selection Table

Parameter Dimensions

Selection Logic

Industry Compatibility Recommendations

VA Content (Vinyl Acetate)

The higher the content, the better the flexibility (5%-25%)

For electronics, choose 15%-20% (excellent cushioning); for industrial applications, choose 5%-10% (higher hardness).

Density

The higher the density, the greater the impact resistance (20-80 kg/m³).

For precision instruments, choose 40-60 kg/m³; for heavy tools, choose 60-80 kg/m³.

Processing

Hot-pressing (excellent waterproofing) vs. sewing (lower cost).

Hot-pressing is essential for outdoor/medical applications.

2. Accessory Quality Identification

Zipper: Professional-grade YKK nylon zippers (≥10,000 engagements) are recommended.

Lining: Mesh bags require 1680D nylon. Polyester (tensile strength ≥ 30N)

Hanging: 304 stainless steel preferred (rust-free after 48-hour salt spray test)

III. Structural Design: Balancing Functionality and Usability

A rational internal layout can improve work efficiency by over 30%, with a focus on logical partitioning and user-friendly design.

1. Zoning Design Principles

Hazard Isolation: Sharp tool areas require a thickened EVA layer (≥5mm thick)

High-Frequency Access: Frequently used tool areas should be within 3cm of the opening

Modularity: Removable dividers accommodate tool upgrades (e.g., a car repair kit can be equipped with a battery storage module)

2. User-Friendly Details

Handheld: Handles must have 3cm thick EVA padding (to reduce hand pressure when carrying a 10kg load).

Shoulder: Strap width ≥8cm, with ventilation holes every 10cm (to prevent sweating during prolonged carrying).

Portable: Folds to 1/3 of its original size (suitable for outdoor emergency tool kits).

4. Compliance Certification: Breaking Down Barriers to International Market Access

After the implementation of new European and American regulations in 2025, compliance has become a key procurement hurdle. Mistaking the wrong approach can lead to customs clearance failures or product recalls. 1. List of Major Market Certifications

2. Certification Pitfall Avoidance Guide

Require suppliers to provide “batch test reports” (not type test reports) to avoid batch discrepancies.

Verify the qualifications of the reporting agency (must be dual-certified by CNAS and CMA).

Specify “joint and several liability for compliance” in the contract (if the EU RAPEX notification rate exceeds 30%, the risk must be transferred).

V. Procurement Decisions: Full-Process Risk Control from Sample to Production

Professional buyers should establish a systematic evaluation system to avoid making decisions based solely on price. 1. Three-step sample testing

Environmental simulation testing: High temperature (60°C/48 hours) and low temperature (-20°C/48 hours) cycles followed by inspection for cracking

Practical verification: Zipper opened and closed 500 times continuously, dropped 10 times with a 20kg load (from a height of 1.2m)

Compliance verification: Send to a third-party agency for retesting of key indicators (such as formamide and heavy metal content)

2. Key supplier screening criteria

Production capacity: Whether an integrated production line is available (from EVA foaming to finished product processing, ensuring more stable quality control)

R&D capabilities: Whether customized lining slotting can be provided (accuracy error ≤ 0.5mm)

Foreign trade experience: Whether there are customs clearance cases in the target market (e.g., IOSS tax registration is required for the EU market)

3. Cost optimization strategy

Select “standard molds” for standard models (saving 30% compared to custom molds)

Batch size ≥ 500 Parts can use “masterbatch foaming” (more environmentally friendly than post-printing).

Agree with the supplier on a “stock rate” (recommended 3% to account for shipping losses).

VI. Common Misconceptions

Color Does Not Equal Antistatic Performance: Black is common due to the presence of conductive carbon black, but lighter colors can achieve antistatic properties through metal oxides (at a 30% higher cost).

Higher Hardness Does Not Equal Better: Medical device packaging requires 38-45° soft EVA (to avoid scratching the device surface).

Certification Does Not Equal Lifetime Validity: The REACH SVHC list is updated every 6 months, and test reports must be reviewed annually.

Post time: Oct-24-2025