How to Evaluate the Protective Performance of EVA Toolkits

The protective performance of EVA toolkits directly determines three key indicators:

Transportation loss rate (resistance to risks such as compression, drops, and moisture in cross-border logistics);

End-customer satisfaction (protection needs of precision products such as industrial tools, electronic equipment, and medical devices);

Compliance costs (whether it meets the industry protection standards of the target market to avoid returns/compliance penalties).

Therefore, relying solely on verbal promises from suppliers or judging from the appearance of samples is far from sufficient; a systematic evaluation system is needed.

I. Core Material: Basic Evaluation of the Protective Performance of EVA Substrate

The protective strength of EVA toolkits stems from the substrate. Buyers need to focus on verifying three key parameters:

1. Density and Hardness (directly related to cushioning and compression resistance)

Evaluation Standard: The density of high-quality protective EVA should be between 38-45 kg/m³ (too low and it is prone to deformation; too high and it lacks cushioning elasticity); the recommended hardness (Shore C) is 40-50 degrees (balancing support and cushioning). Purchaser’s Practical Methods:

1. Request the supplier to provide a third-party testing report (indicating density/hardness data);

2. Sampling Test: Directly measure the sample with a hardness tester, or conduct a compression test on tool bags of the same specifications (apply 50kg pressure for 10 minutes; no permanent deformation after release indicates it is qualified).

2. Closed-Cell Structure Integrity (Key to Moisture Proof and Corrosion Resistance)

The closed-cell rate of EVA directly affects its moisture-proof performance—a closed-cell rate ≥95% is necessary to effectively block moisture and oil penetration (especially suitable for outdoor tools and electronic equipment packaging).

Evaluation Methods:

Immersion Test: Soak the EVA liner for 24 hours and observe whether it absorbs water and swells (qualified products have a water absorption rate ≤1%);

Microscopic Observation: Request the supplier to provide a cross-sectional micrograph to confirm that the closed cells are undamaged and have no interconnected pores. 3. Weather Resistance and Aging Resistance (Adaptability to Different Global Climates) International procurement needs to cover different regional climates (high temperature, low temperature, high humidity). EVA materials must pass weather resistance testing: Key Indicators: 50 cycles of testing at -40℃ to 70℃, no cracking, discoloration, or hardness change within ±5 degrees. Procurement Focus: Suppliers are required to provide ISO 4892-2 (artificial accelerated aging) test reports to avoid premature toolkit failure due to climate differences.

II. Structural Design: “Secondary Reinforcement” of Protective Performance

Even with the same EVA substrate, differences in structural design can lead to drastically different protective effects. Procurers need to focus on 4 key points:

1. Liner Fit (Core of Targeted Protection) Evaluation Criteria: The fit gap between the toolkit liner and the target product (such as wrenches, sensors, medical devices) should be ≤2mm, with no loose space (excessive gaps can easily lead to collision damage during transportation). Practical Recommendation: Request the supplier to provide a 3D fit diagram of the “product – lining,” or send samples for actual assembly testing (simulating the bumpy conditions of cross-border transportation).

2. Sealing and Protection Design (Moisture-proof, Dust-proof, Impact-resistant)

Edge Sealing: Check the integrity of the zipper/Hook and Loop seal (high-quality products will add waterproof adhesive strips, with a protection level of IP54 or higher);

Impact-resistant Structure: Observe whether there are multiple layers of EVA, honeycomb cushioning layers, or corner reinforcement designs (which can reduce the impact force transmission by more than 30% in drop tests).

3. Load-bearing and compression resistance (bulk stacking and transportation requirements) After wholesale purchase, tool bags need to be stacked for storage/transportation. The tool bags must meet the following requirements: Stacking test: 5 tool bags stacked (total weight ≤ 30kg) for 24 hours, with no collapse or deformation at the bottom; Handle/shoulder strap load-bearing capacity: Suspending a 10kg weight for 30 minutes, with no tearing at the joints and no loosening of the seams (especially suitable for industrial-grade tool bags).

4. Reinforced corner protection (focusing on vulnerable areas) The corners of tool bags are high-risk areas for impacts. High-quality products will use: Thickened EVA (corner thickness 20% greater than the main body); Hard plastic edging or metal reinforcement; Evaluation method: Impact the corners with a 1kg steel ball from a height of 1 meter and observe for cracking and displacement of the lining.

III. Simulated Scenario Testing: Reproducing Protective Performance in Real-World Use

Laboratory data must be verified in conjunction with actual scenarios. Purchasers may request the supplier to provide the following three types of core test reports (or conduct their own sampling tests):

1. Drop Test (High-Frequency Scenarios in Cross-Border Transportation)

Standard Reference: ASTM D5276 (International Standard for Drop Testing of Transport Packaging);

Test Requirements: After the tool package carries the target product, it is dropped freely from a height of 1.2 meters (simulating forklift handling drop) 10 times (6 sides + 4 corners). The internal product shows no scratches and no functional abnormalities.

2. Environmental Adaptability Test (Multi-Regional Market Demands)

Moisture Resistance Test: Placed in an environment with 85% humidity and 40℃ for 72 hours, there is no condensation inside and the product is not damp;

Corrosion Resistance Test: Placed in a salt spray environment (5% NaCl solution) for 48 hours, metal fittings (zippers, buckles) show no rust, and EVA shows no discoloration. 3. Customized Testing for Special Scenarios (Selectable on Demand)

* **Anti-static Requirements (Electronic Equipment Purchasers):** The surface resistance of the EVA toolkit must be between 10⁶ and 10¹¹Ω (compliant with ANSI/ESD S20.20 standards);

* **Low Temperature Environment (Purchased in High-Latitude Regions):** After being placed at -30℃ for 24 hours, there should be no cracking, and the elastic recovery rate should be ≥90%;

* **Abrasion Resistance Test (High-Frequency Use Scenarios):** After 1000 abrasion cycles using an abrasion tester (1kg load), the surface should show no damage or shedding.

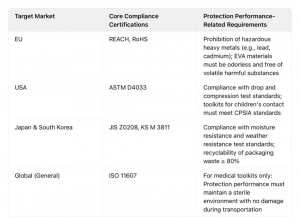

IV. International Compliance Certification: Avoiding Market Access Risks

Different regions globally have specific compliance requirements for packaging materials. Buyers need to verify the following certifications (directly affecting customs clearance and market sales):

V. Quality Stability Assessment for Bulk Procurement (Key Pitfalls)

Wholesale procurement is most vulnerable to “high-quality samples, but substandard bulk orders.” Stability needs to be verified through two dimensions:

1. Sampling Inspection Ratio

Sampling should be conducted according to ISO 2859 standards: When the batch size is ≥1000 pieces, the sampling ratio should be ≥3% (with a minimum of 30 pieces). Key areas to check include:

* Consistency of density/hardness (error ≤5%);

* Uniform standards for lining fit and sealing performance;

* Occurrence rate of appearance defects (such as bubbles, cracks, loose stitching) ≤0.5%. 2. Supplier Quality Control System

Requires ISO 9001 quality management system certification;

Verify the production process: Are there complete records of raw material inspection, semi-finished product testing, and finished product inspection?

Confirm whether third-party testing (e.g., SGS, Intertek) is supported; unconditional returns and exchanges are allowed for products that fail testing.

VI. Procurement Decision Summary: From “Passive Reception” to “Proactive Evaluation”

International buyers evaluate the protective performance of EVA toolkits by establishing a four-dimensional system of “parameters + testing + compliance + stability”:

First, clarify their own needs (target product weight, transportation method, target market compliance requirements);

Require suppliers to provide “material parameter tables + third-party test reports + certification certificates”;

Conduct sampling tests in core scenarios (drop, moisture resistance, fit);

Clearly define compensation clauses for “non-compliance with protective performance” in the contract (e.g., returns, compensation for transportation losses).

Post time: Nov-17-2025