What Parameters Are Required for a Customized EVA Tool Bag?

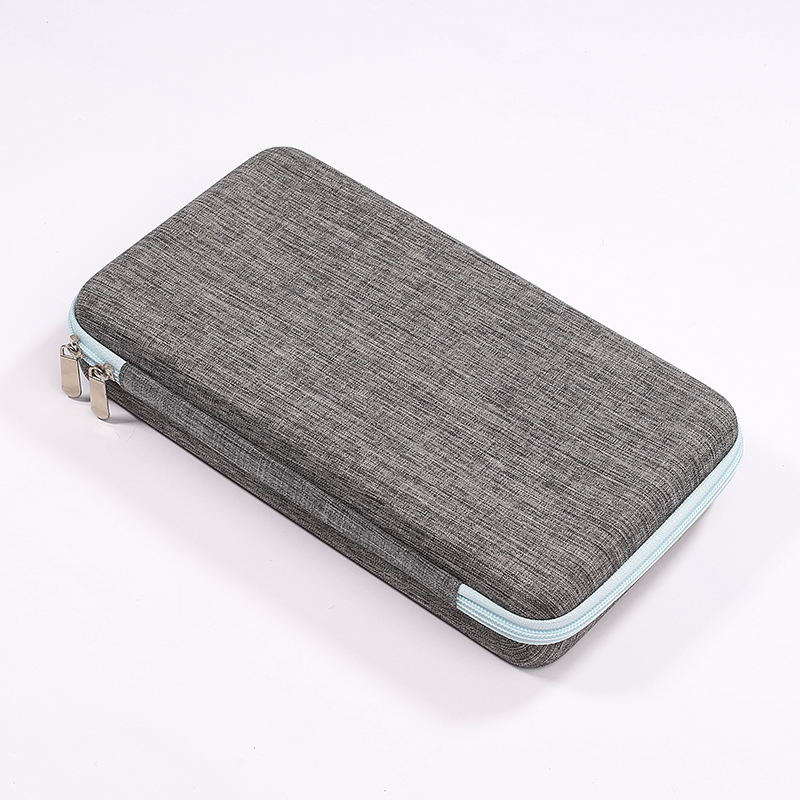

In numerous fields, including industrial production, electronics repair, medical care, and outdoor work, EVA tool bags, with their excellent shock absorption, waterproof and wear-resistant properties, and lightweight portability, have become essential tools for protecting tools and improving work efficiency. However, generic EVA tool bags on the market often fail to perfectly meet the tool storage needs of different industries and scenarios. Tools may not fit properly, improper compartments may cause damage due to shaking, or they may be too large to be easily carried. In these cases, a custom EVA tool bag becomes the optimal solution.

However, customizing an EVA tool bag isn’t as simple as simply “naming your request”; it requires you to clearly define a series of key parameters in advance so that the manufacturer can accurately understand your needs and ultimately deliver a product that meets your expectations. Today, we’ll analyze the core parameters required for a custom EVA tool bag from multiple perspectives to help you avoid customization pitfalls and efficiently complete your tool bag customization. 1. Basic Specifications: Determining the Tool Bag’s “Innate Framework”

Basic specifications are the “skeleton” of an EVA tool bag, directly determining whether it can accommodate core tools and meet the space requirements of the intended use scenario. These specifications are the “first step” in customization and must be accurate; otherwise, all subsequent design efforts will be wasted.

First. External Dimensions: Precisely Matching “Tools + Use Scenario”

The external dimensions of an EVA tool bag primarily consist of three key parameters: length, width, and height. These parameters are determined based on two factors:

Total Tool Dimensions: First, lay out or stack all the tools you need to store (including the largest and smallest) and measure the total length, width, and height. Then, allow 5-10cm of “redundant space”—this prevents overcrowding and makes it difficult to access tools, while also allowing for the cushioning of the EVA lining. For example, if you need to store a set of 30cm long electronics repair tools, the recommended tool bag length is 35-40cm to ensure the tools fit comfortably and without shaking.

Use scenario limitations: If the tool bag is to be carried on the person (e.g., a tool bag for outdoor maintenance personnel), ergonomic considerations must be taken into account. The width is recommended to be no more than 40cm (to avoid shifting the center of gravity when carried on one shoulder) and the height no more than 50cm (to allow for easy fit when carried by hand or across the body). If the tool bag is to be stored in a vehicle, the available space in the trunk or under the seat should be measured to ensure the tool bag is too large to fit.

Also, the external shape must be clearly defined: is it a conventional rectangular or cube-shaped tool, or is it a special shape (e.g., curved or trapezoidal) designed for specialized tools? For example, a tool bag for storing cylindrical instruments can be designed with curved sides to reduce space waste and improve protection. 2. EVA Material Parameters: Determine the Tool Bag’s Durability and Protection

EVA material is the core of a tool bag. Its parameters directly affect its cushioning capacity, water resistance, and lifespan. The following three key points should be clearly understood:

Density: EVA density is typically expressed in kg/m³, with a common range of 200-800 kg/m³. Lower density indicates lighter and more flexible material (suitable for protecting delicate electronic components and glassware); higher density indicates harder and more wear-resistant material (suitable for protecting heavy tools like wrenches and hammers). For example, for a custom tool bag designed to store mobile phone repair tools (such as screwdrivers and tweezers), choose a low-density EVA material of 300-400 kg/m³. This provides cushioning without adding weight. For a custom bag designed to store auto repair tools, a high-density EVA material of 600-700 kg/m³ is recommended to resist friction and compression from the tools. Hardness: EVA hardness is measured in “Shore C,” typically ranging from 20 to 80 Shore C. Hardness is positively correlated with density, but not absolutely so—some low-density EVA can achieve higher hardness through process adjustments. If the tool bag will be frequently opened and closed (such as for daily maintenance), it is recommended to choose a medium-hardness EVA of 30 to 50 Shore C, which balances flexibility and support to prevent edge cracking after long-term use. If the tool bag is used for long-term storage (such as an instrument spare bag), choose a high-hardness EVA of 60 to 70 Shore C to ensure that the tool bag maintains its shape and resists deformation. Surface Treatment: The surface treatment of EVA material directly affects its water resistance and abrasion resistance. Common options include:

Regular bare EVA: Low cost, suitable for storing tools in dry environments, but with limited water resistance;

Coated EVA: Covered with a PVC or PU film, this significantly improves water resistance and is easy to clean (oil and dust can be wiped off with a damp cloth). It is suitable for outdoor and humid environments (such as plumbing and electrical maintenance, and aquaculture equipment tool kits);

Flocked EVA: Attached with a layer of fleece, it has a soft touch and effectively prevents scratches on tool surfaces (suitable for storing metal tools and painted instruments). However, be aware that flocking is dust-sensitive and unsuitable for dusty environments.

Second. Functional Compatibility Parameters: Making the Tool Bag “Useful and Practical”

The basic specifications define the “framework” of the tool bag, while the functional compatibility parameters determine its “usability”—whether the tools can be clearly organized, easily accessed, and whether it can meet the needs of specific scenarios. These parameters should be determined based on the characteristics of the tools and usage habits.

1. Internal Structure Design: Achieving “No Tool Clutter, No Time-consuming Removal and Retrieval”

One of the core advantages of the EVA tool bag is its customizable internal dividers, which prevent tools from colliding or becoming entangled. Therefore, the following structural parameters must be clearly defined:

Divider Method: Select the appropriate divider design based on the tool type:

Fixed Slots: For tools with regular shapes and fixed sizes (such as screwdrivers, wrenches, and testers), design a “grooved” slot that perfectly matches the tool. Once inserted, the tool is securely positioned and prevents it from falling out, even if the tool bag is inverted. The precise dimensions of the tool (length, width, height, and diameter) must be provided during the design process, and even physical or 3D models of the tool must be provided to ensure the slots fit perfectly.

Removable Dividers: For applications where the number and size of tools frequently change (such as multi-purpose maintenance tool bags), removable dividers with slots can be designed, allowing users to adjust the space as needed. The number of dividers, the dimensions of each divider, and the spacing between the slots (5cm is recommended for flexible adjustment) must be clearly defined. Mesh Pockets/Elastic Bands: For small, loose tools (such as screws, washers, and wires), mesh pockets (recommended to be made of nylon, which is durable and transparent for easy viewing) or elastic bands (suitable stretch to prevent tools from slipping) can be designed on the sides or top of the tool bag. The size and quantity of the mesh pockets, as well as the length and width of the elastic bands (recommended width: no less than 1cm to avoid constriction), should be specified.

2. Opening, Closing, and Carrying Methods: Adapting to “Frequency of Use and Scenario”

The opening, closing, and carrying methods of the tool bag directly impact its efficiency and should be determined based on user habits:

Opening and Closing Methods:

Zipper Closure: The most common method provides a good seal and is suitable for applications requiring dust and water protection (such as electronic instrument tool bags). The zipper material (nylon zippers are lightweight, metal zippers are durable), size (recommended width: no less than 1cm to prevent breakage), and whether a “double zipper pull” is required (for easy opening and closing from both sides, improving access efficiency) should be specified. Velcro closure: Fast opening and closing, suitable for frequent tool access (such as field repair tool kits). However, its sealing performance is poor, making it unsuitable for applications requiring high dust and water resistance. The Velcro width (recommended at least 2cm to ensure sufficient adhesion) and location (e.g., full-width Velcro on the top of the tool kit, or partial Velcro on the side) should be specified.

Buckle closure: Highly stable, suitable for heavy tool kits (such as auto repair kits), to prevent the closure from loosening due to the weight of the tools. The material of the buckles (plastic buckles are lightweight, metal buckles are durable) and the number of buckles (recommended 2-4, evenly distributed around the edges of the tool kit) should be specified.

Carrying method:

Hand-held: Suitable for lightweight tool kits (under 5kg) and short-distance transport. The material of the hand strap (nylon or canvas, recommended width at least 3cm to avoid constriction) and length (the bottom of the tool kit should be 10-15cm off the ground when carried by hand) should be specified, as well as whether a “sponge hand guard” is required (to improve carrying comfort). Single-shoulder/cross-body: Suitable for medium-weight tool bags (5-10kg) and situations where hands-free use is necessary (such as outdoor maintenance). You’ll need to specify the shoulder strap material (breathable mesh is recommended to avoid excessive heat during prolonged carrying), length (adjustable range recommended: 80-120cm, suitable for people of different heights), and whether a chest buckle is required (to prevent the strap from slipping).

Double-shoulder: Suitable for heavy tool bags (over 10kg) and long-distance carrying (such as field work). You’ll need to specify the shoulder strap width (minimum 5cm to distribute shoulder pressure), the carrying system (whether a lumbar support or chest strap is required for improved stability), and whether a back strap with breathable foam is required (to reduce back sweating).

Third, Appearance and Logo Parameters: Making the Tool Bag Recognizable and Brand-Friendly

Beyond practicality, the appearance and logo of a tool bag are also crucial—especially for customized company-made tool bags, which serve not only as a storage medium for tools but also as a “mobile promotional tool” for the brand. These parameters need to be determined based on the brand positioning and usage scenarios.

1. Color Selection: Balancing “Recognition and Functionality”

The color of an EVA tool kit isn’t necessarily “the more beautiful the better”; it should be selected based on the usage scenario and needs:

Highly Recognizable Colors: If the tool kit is used for outdoor work or emergency repairs (such as power repairs or fire rescue), bright colors such as red, orange, or bright yellow are recommended. This not only makes it easier to find the tool kit in complex environments, but also improves worker safety (avoiding accidental collisions).

Understated Professional Colors: If the tool kit is used in medical settings (such as first aid kits for medical staff) or electronic device repair (such as mobile phone after-sales service kits), understated colors such as white, light gray, or dark blue are recommended. White and light gray appear clean and hygienic, suitable for medical settings; dark blue appears professional and calm, suitable for electronic repairs.

Branded Colors: If the tool kit is used for corporate employee distribution, choose a color that aligns with the brand’s VI (such as Huawei’s “Huawei Red” or Xiaomi’s “Xiaomi Orange”) and complements it with the brand logo to enhance brand recognition. In addition, be aware that EVA materials may have color variations. It’s recommended to ask the manufacturer for color charts and select the color closest to your desired color. It’s also recommended to specify in the contract that “the color variation range does not exceed XX%” to avoid color discrepancies upon receipt.

2. Logo and Printing: Creating “Distinctive Identity”

One of the core advantages of custom tool kits is the ability to add unique logos. Common logo types include:

Logo Printing: Printing your company logo or brand name on the surface of the tool kit (such as the front or side). The size, position, color, and printing process of the logo must be specified.

Silkscreen Printing: Suitable for simple, single-color logos. It offers low cost and clear printing, and is suitable for most EVA materials.

Heat Transfer Printing: Suitable for multi-color, complex logos. It offers vibrant colors and strong adhesion, but is more expensive and is suitable for applications requiring a high-quality appearance (such as gift-grade tool kits).

Laser Engraving: Engraving your logo onto the EVA surface creates a neutral, debossed, or raised effect, creating a premium, wear-resistant look. It’s suitable for high-density EVA materials. Other Labeling: If the tool kit is shared by multiple people (e.g., in a factory workshop), you may want to add a name tag slot and printed serial number. If the tool kit contains dangerous tools (e.g., sharp knives or high-voltage instruments), you may want to print warning labels (e.g., “Caution: Sharp” or “High Voltage”) on the surface to enhance safety.

IV. Special Requirements Parameters: Meeting “Personalized and Scenario-Specific” Requirements

In addition to the general parameters listed above, if your EVA tool kit has specific usage scenarios or personalized requirements, you should also specify the following parameters to ensure it is fully compatible with your needs.

1. Waterproof, Dustproof, and Corrosion-Resistant Requirements

Waterproof Rating: If the tool kit is used in humid environments (e.g., aquaculture or outdoor work in the rain), you should specify the waterproof rating. Common ratings are IPX4 (splashproof), IPX5 (sprayproof), and IPX6 (powerful water jets). If complete waterproofing is required (e.g., if the tool bag might be dropped into water), an IPX7 or IPX8 rating should be selected. Manufacturers will use a “fully sealed zipper + coated EVA + waterproof tape” design to prevent moisture from seeping in.

Dustproof rating: If the tool bag will be used in dusty environments (such as construction sites or flour mills), the dustproof rating should be specified. Common ratings are IP5X (protects against most dust ingress) and IP6X (completely protects against dust ingress). In this case, the tool bag’s opening and closure should be designed with a “sealing tape + dust screen” design to prevent dust from entering and contaminating the tools.

Corrosion resistance requirements: If the tool bag will store corrosive tools (such as acidic and alkaline solutions, chemical reagents), choose a corrosion-resistant EVA material (such as EVA with an anti-corrosion agent) and design an internal “corrosion-resistant lining” (such as a PTFE-coated lining) to prevent the tools from corroding the tool bag, and to prevent the tool bag from corroding and contaminating the tools.

2. Temperature Compatibility Requirements

EVA material has certain operating temperature limitations. Conventional EVA is suitable for temperatures between -20°C and 60°C. If your tool kit will be used in extreme temperature environments, you need to clearly specify the temperature requirements:

Low-temperature environments (such as polar operations or freezer tool storage): Choose “low-temperature-resistant EVA material” to ensure it remains flexible and resists cracking at temperatures below -40°C.

High-temperature environments (such as metallurgical workshops and boiler maintenance): Choose “high-temperature-resistant EVA material” to ensure it retains its shape and resists melting at temperatures above 80°C.

Also, you need to inform the manufacturer of the operating temperature of the tools stored in the tool kit. If the tools themselves generate heat (such as small motors or heating equipment), heat dissipation holes or insulation layers should be designed into the tool kit to prevent deformation of the EVA material caused by heat generation.

3. Custom Quantity and Lead Time

Custom Quantity: The cost of customizing an EVA tool kit is closely related to the quantity ordered. The higher the quantity, the lower the unit cost (because mold and pattern making costs can be amortized). The minimum order quantity (MOQ) and the total custom quantity must be clearly stated: If you are ordering for an individual or in small quantities (e.g. 10-50 pieces), you must choose a manufacturer that supports small-batch customization to avoid being unable to customize due to insufficient quantity; if you are ordering for a large quantity (e.g. more than 1,000 pieces) for an enterprise, you can negotiate with the manufacturer to reduce the unit price and request a “sample”"Product confirmation” (produce 1-2 samples first, and then proceed to mass production after confirmation).

Delivery Time: It’s important to clearly define the tool kit’s “delivery time” and consider the manufacturer’s production cycle. For standard small-batch customization (less than 100 pieces), the lead time is approximately 7-15 days (including design, mold making, production, and quality inspection); for large-batch customization (over 1,000 pieces), the lead time is approximately 20-30 days. For urgent needs (such as trade show gifts or urgent project requirements), it’s important to communicate with the manufacturer in advance to confirm whether “expedited production” is available and to specify the expedited fee (usually 10%-30% of the regular fee).

Conclusion: Clarifying the parameters is key to customizing the “perfect tool kit.”

Customizing an EVA tool kit is a process of “needs and details collide.” The more precise and comprehensive the specifications you provide, the more accurately the manufacturer will understand your needs, and the more accurately the final tool kit will meet your expectations. From basic dimensions and materials to functionally compatible internal structures and carrying methods, as well as external markings and special requirements, every parameter directly impacts the user experience of the tool kit.

Post time: Oct-10-2025